3D printer solutions

3D printing is a kind of rapid prototyping technology, which is based on digital model files, using powdered metal or plastic and other bondable materials to construct objects by printing layer by layer.

3D printing is usually achieved by using digital technology material printers. It is often used to make models in the fields of mold manufacturing, industrial design, etc., and then gradually used in the direct manufacturing of some products, in jewelry, footwear, industrial design, architecture, engineering and construction (AEC), automotive, aerospace, dentistry, and There are applications in the medical industry, education, geographic information systems, civil engineering, guns, and other fields.

3D printing advantages: Take 3D printing shoe soles as an example. Compared with traditional shoe sole manufacturing, 3D printing has the advantage of not being restricted by molds.

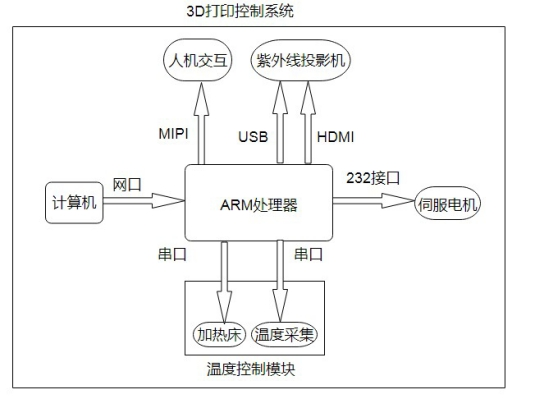

The 3D printing control system is as follows:

1. Computer: As the upper computer design side, it is used to initialize the configuration of the core control board integrated with the ARM microcontroller, and process the 3D model of the printed object through the slicing software and generate instructions, and then store it in the data storage module middle.

2. The core control board of the ARM controller: used to read the instructions in the data storage module, the instructions include motion trajectory planning and motion control information, and analyze the instructions to generate corresponding control instructions to control the 3D printer Work.

3. Servo motor drive module: used to control the rotation accuracy of the axial motor and feeder of the 3D printer;

4. Temperature control module: control the temperature to solidify the material.

5. Liquid crystal display: MIPI screen, used to display the working menu of the 3D printer and receive user selection instructions, and send the selection instructions to the core control board integrated with the ARM microcontroller;

6. Ultraviolet projector: HDMI interface outputs a high-definition resolution video image signal, and then the video is irradiated to the photosensitive liquid resin with ultraviolet rays through an optical instrument, so that the photosensitive resin is cured into the corresponding shape; The USB interface is used to control the intensity of ultraviolet light emitted by the projector and the switch of the ultraviolet projector. At the same time, the ultraviolet light machine will also return the real-time ultraviolet light intensity value of the light machine to the ARM for closed-loop control.

In summary, the USB signal controls the UV projector, and the HDMI signal will also output high-definition resolution images to the UV projector.

Introduction to the configuration scheme

The LQ3399 core board is based on the RK3399 processor design of Rockchip.

Equipped with two Cortex-A72 cores, clocked at 1.8GHZ; four Cortex-A53 cores, clocked at 1.4GHZ;

Possesses a variety of display interfaces, including HDMI2.0, MIPI DSI, EDP1.3, DP1.2; the maximum resolution is 4K, supports dual-screen simultaneous display, dual-screen different display;

Provide a variety of peripheral interfaces, PCIE, USB3.0, UART, IIC, SPI, etc.